It’s a common issue that can drive any car owner to frustration - tires losing air. Understanding why this happens and how to address it is crucial for maintaining your vehicle’s performance and your safety on the road.

Table of Contents

Understanding Tire Air Loss

Tires naturally lose air over time due to a process called osmosis. In short, it is the natural process where air molecules pass through the tire rubber from an area of high concentration (inside the tire) to an area of low concentration (outside the tire). Over time, this results in a gradual loss of air pressure in the tire.

Additionally, temperature changes can significantly affect tire pressure. For instance, a drop in temperature can cause the air inside the tires to contract, leading to a decrease in tire pressure.

Common Causes of Tire Air Loss

Wheel Issues

Poor valve stem conditions and damaged wheels can cause your tires to lose air. Over-tightening valve cores or exposure to harsh chemicals on the road can deteriorate valve stems, leading to air loss. Similarly, a wheel that has been dented or corroded can also lead to a slow leak.

Temperature Changes

Temperature fluctuations can cause your tires to lose air. As the temperature drops, the air inside the tire contracts, leading to a decrease in tire pressure. Conversely, as the temperature rises, the air expands, increasing the tire pressure.

Faulty Valve Stem

A faulty valve stem can cause your tire to lose air. This could be due to damage, wear and tear, or improper installation during the last tire service.

Missing Valve Caps

Missing valve caps can lead to air loss. The cap helps to keep out dirt and debris that could interfere with the valve stem and cause a leak.

Tire Damage

Tire damage is a common cause of air loss and can occur in several ways.

One of the most frequent culprits is the presence of sharp objects such as nails or screws that can puncture the tire, causing it to lose air slowly.

These punctures often occur when driving over road hazards like debris or sharp objects. Even a small puncture can lead to a significant amount of air loss over time.

In addition to punctures, bead damage can also lead to air loss. The bead of a tire is the edge that fits snugly against the rim of the wheel, creating an airtight seal. Any damage to this sealing surface between the rubber of the tire and the metal of the rim can cause a loss of air.

Bead damage can occur due to a variety of reasons, including improper mounting of the tire, impact from hitting a curb or pothole, or even corrosion of the rim.

Furthermore, the age of the tire can also contribute to bead damage and subsequent air loss.

As tires age, the rubber can weaken and lose its elasticity. This weakening can lead to the breaking of the seal between the tire and the rim, allowing air to escape. This is particularly true for tires that are exposed to harsh environmental conditions or are not regularly maintained.

Therefore, it’s important to regularly check the condition of your tires, especially as they get older, to prevent slow leaks due to bead damage or other forms of tire damage. Regular tire maintenance and timely replacement can help prevent these issues and ensure the longevity and safety of your tires.

Locating the Air Leak

Locating a tire air leak can be done by listening for a hissing sound or feeling for air escaping from the tire. Another effective method is using soapy water. By spraying the tire and rim edge with a soapy water mixture, bubbles will appear where the leak is present. Alternatively, you can immerse the wheel in water and look for bubbles that indicate a leak.

Repairing the Tire

Punctured tires can be repaired using sealants or a special plug kit. These methods can effectively patch up the puncture, preventing further air loss.

Using a Sealant:

- Purchase a Tire Sealant.

- Locate the Puncture: Find the puncture in your tire. This is usually where the nail or sharp object has entered the tire.

- Apply the Sealant: Follow the instructions on the sealant package. Usually, you will need to attach the hose of the sealant bottle to the valve stem of your tire and squeeze the bottle to inject the sealant into the tire.

- Drive Your Vehicle: Drive your vehicle for a short distance. This allows the sealant to spread evenly inside the tire and seal the puncture.

- Check the Tire Pressure: After driving for a few minutes, check the tire pressure to ensure that the tire is properly inflated.

Using a Plug Kit:

- Purchase a Plug Kit: Buy a tire plug kit from an auto parts store. The kit usually includes a reaming tool, plug tool, plugs, and rubber cement.

- Locate the Puncture: Find the puncture in your tire.

- Prepare the Puncture: Use the reaming tool from the kit to clean and prepare the puncture for the plug.

- Insert the Plug: Thread a plug through the eye of the plug tool. Apply rubber cement to the plug and insert the plug into the puncture using the plug tool.

- Remove the Plug Tool: Once the plug is inserted, quickly pull out the plug tool. The plug will remain in the tire and seal the puncture.

- Check the Tire Pressure: Check the tire pressure to ensure that the tire is properly inflated.

| Brand | BETOOLL |

|---|---|

| Weight | 1.17 pounds |

| Dimensions | 9 x 6 x 2 inches |

| Features | Universal kit for Car, Motorcycle, ATV, Truck, Tractor |

Repairing the Valve Stem

Replacing a faulty valve stem can stop the air loss. This involves removing the old valve stem and installing a new one.

The following step-be-step process will guide you on how to replace a faulty valve stem:

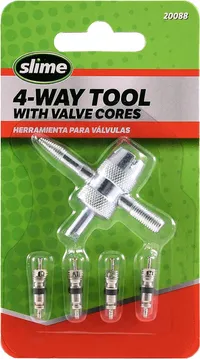

- Purchase a New Valve Core and Valve Core Removal Tool: These can be found at any auto parts store. The removal tool is specifically designed to easily remove and install valve cores.

- Remove the Valve Cap: Unscrew the valve cap from the valve stem and set it aside.

- Use the Valve Core Removal Tool: Insert the removal tool into the valve stem and engage with the valve core. Turn the tool counterclockwise to unscrew the valve core from the valve stem. Be careful during this step as the pressurized air in the tire will rapidly escape once the valve core is removed.

- Inspect the Valve Stem: Once the valve core is removed, inspect the valve stem for any signs of damage or wear. If the stem itself appears damaged, it may need to be replaced entirely.

- Install the New Valve Core: Place the new valve core into the valve stem and use the removal tool to screw it in clockwise. Make sure it’s snug, but be careful not to overtighten it as this could cause damage.

- Reinflate the Tire: With the new valve core installed, you can now reinflate the tire to the manufacturer’s recommended tire pressure.

- Replace the Valve Cap: Screw the valve cap back onto the valve stem. This helps to protect the valve core from dirt and debris.

Remember, while this process can be done at home, if you’re not comfortable doing it yourself, it’s always best to take your vehicle to a professional. They have the right tools and knowledge to ensure the job is done correctly and safely.

Repairing and/or Restoring the Rim

Repairing a bent wheel or restoring a corroded rim can help stop the tire from losing air. This might involve straightening the wheel or removing the corrosion.

Importance of Tire Pressure

Maintaining the right tire pressure is crucial for safety, load-carrying capacity, tire lifespan, and fuel consumption. Improper tire pressure can lead to unstable vehicle handling, increased risk of flats and blowouts, premature tire wear, and increased fuel consumption.

Maintaining Proper Inflation

Regularly checking your tire pressure and maintaining proper inflation can help prevent your tires from losing air. This involves using a calibrated pressure gauge to check the pressure and adding or releasing air as needed.

Checkout our step by step guide on How to put air in tires.

Conclusion

In conclusion, tires can lose air due to a variety of reasons, including wheel issues, tire damage, temperature changes, faulty valve stems, and missing valve caps. Locating the leak and fixing the issue promptly can help maintain your vehicle’s performance and ensure your safety on the road. Regular tire pressure checks and maintaining proper inflation are key to preventing your tires from losing air.